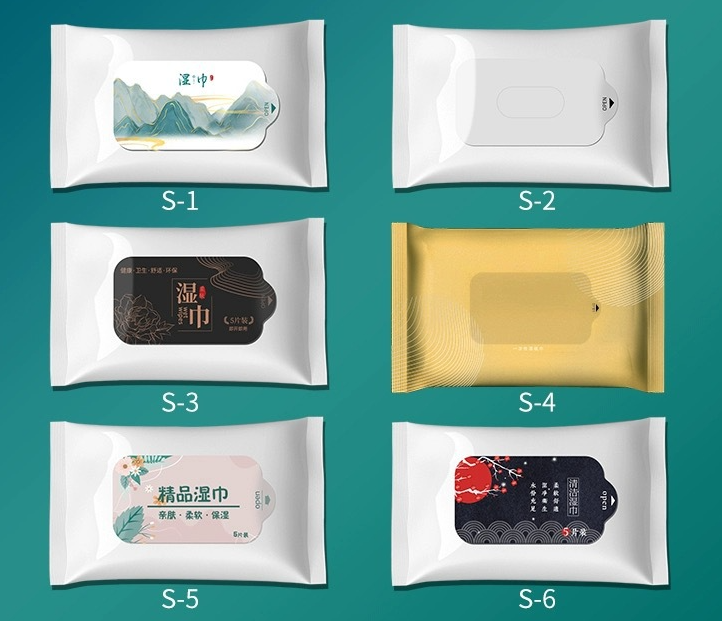

sealed wipes manufacturer

A sealed wipes manufacturer specializes in the production of pre-moistened wipes packaged in airtight containers, ensuring product integrity and prolonged shelf life. These facilities employ state-of-the-art manufacturing processes, incorporating advanced automation systems and quality control measures throughout the production cycle. The manufacturing process begins with carefully selected non-woven materials, which undergo specialized treatment to enhance their absorption and cleaning capabilities. The facility utilizes precision equipment to apply the perfect amount of cleaning solution or treatment formula to each wipe, ensuring consistent quality and performance. The manufacturing environment maintains strict hygiene protocols, operating in clean room conditions to prevent contamination. Advanced sealing technology ensures each package remains hermetically sealed, preserving the wipes' moisture content and preventing bacterial growth. These manufacturers typically offer customization options, including various packaging sizes, material choices, and formula compositions to meet specific customer requirements. Quality assurance systems monitor every aspect of production, from raw material testing to final product inspection, ensuring compliance with international standards and regulations. The facility's capabilities extend to producing wipes for various applications, including personal care, industrial cleaning, medical use, and specialized commercial purposes, all while maintaining the highest standards of quality and safety.